A few weeks ago the FAA released a draft version of its Vertiport Design Engineering Brief. I have compiled the most important information that would be applicable to fire protection professionals who may be reviewing these plans, working through a concept of operations, or ultimately required to respond to emergencies.This document has been created to provide facility design guidance for VTOL aircraft powered by “electric motors and utilizing distributed electric propulsion in contrast to propulsion systems built solely around an internal combustion engine.” This guidance applies to modification of existing facilities and construction of new facilities. This guide is required to be followed by any vertiport projects that receive federal funding and by federally obligated airports. These facilities will also be required to comply with 14 CFR Part 135, Operating Requirements: Commuter and On Demand Operations and Rules Governing Persons On Board Such Aircraft.

This design guide is based on pilot-on-board, visual flight rule operations, and aircraft characteristics as modeled in the below chart. The chart below was created from a composite of nine different eVTOL aircraft currently being developed.

Terminology and Definitions

Composite Aircraft: the composite aircraft represents an VTOL aircraft that integrates the performance and design characteristics of nine VTOL aircraft currently in development. This composite aircraft is used to specify the performance and design characteristics for the purposes of vertiport design in this engineering brief.

Controlling dimension (CD): The CD is the longest distance between the two outermost opposite points on the design VTOL aircraft (e.g., wingtip-to-wingtip, rotor tip-to-rotor tip, rotor tip-to-wing tip, fuselage-to-rotor tip), measured on a level horizontal plane that includes all adjustable components extended to their maximum outboard deflection.

Design VTOL aircraft: The design VTOL aircraft is the largest electric, hydrogen, or hybrid VTOL aircraft that is expected to operate at a vertiport. This design aircraft is used to determine the size of the TLOF, FATO and safety area. Note that the design VTOL aircraft is different from the composite aircraft used to define the performance and design criteria in this engineering brief.

Vertiport Dimensions and Markings

Any vertiport that is being built on a federally obligated airport must submit an Airport Laoyout Plan (ALP). Current heliport facilities that are being converted to vertiports will be required to submit a Form 7480-1 for re-designation as a vertiport. Additionally, any State of local regulations must be followed. These can be found at, https://www.faa.gov/airports/resources/state_aviation/.

The VTOL landing area is required to be based on the controlling dimension (CD) of the design aircraft that will be using the facility. Those design criteria are depicted below:

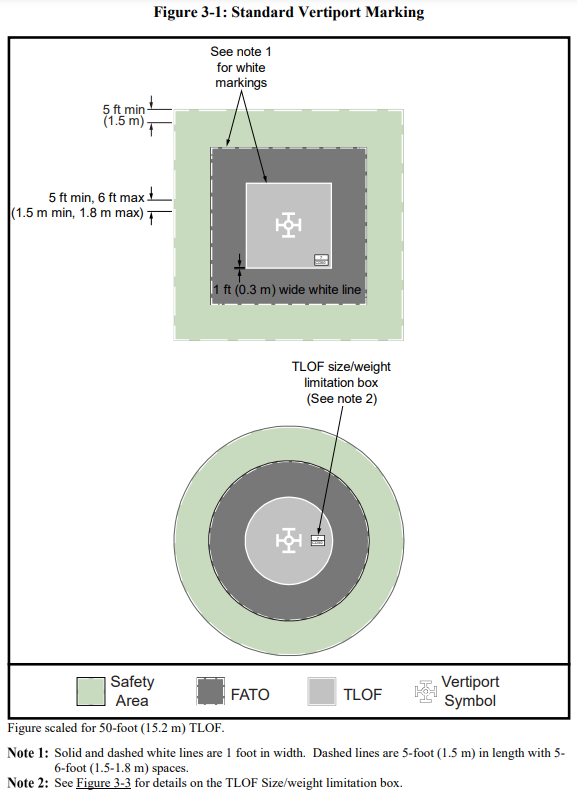

The vertiport landing and safety areas are required to be marked as shown in the diagram below:

This brief also establishes and defines the an official vertiport identification marking:

Charging and Infrastructure

This engineering brief acknowledges the hazards and challenges of eVTOL charging and infrastructure. “Current charging standards for light duty vehicle charging (up to 350kw) align with multiple light electric aircraft currently applying for certification. However, higher capacity batteries and novel systems for meeting operation characteristics may require alternative chagrin methods including mobile charging systems, fixed battery storage, cable and/or on-board battery cooling, or other concepts.” The guide then refers the user to a collection of standards that should be reviewed and applied.

Firefighting Considerations

A brief section on firefighting acknowledges that there is no clear guidance on extinguishing fires related to these VTOL aircraft. A study is cited that states water is more effective for cooling, preventing thermal runaway, and containing the fire than was gaseous or dry powder agents. New technology on the horizon may prove to be even more effective than what is currently available. The hazards that responders should be prepared for and have an understanding of, include:

Important Dates

The Engineering Brief and all related information can be accessed at the website here, https://www.faa.gov/airports/engineering/engineering_briefs/drafts/.